Designing skis for my wife

The next project is a pair of skis for my wife. So far I’ve gone through some of the cad and graphical design setup before I can proceed with preparing the layers and top sheet. Here’s the auto cad setup of the design. the ski shape below in magenta is a top down view of the design. the blue and red linework is unfinished but will be the core profile, which tapers at the front and back of the ski, and the camber/rocker profile under that:

The ski is going to be 146 cm long, with a 137 cm running length. The nose/tail/waist widths will be 121/77/111 mm and stance setback 85 mm, resulting in a sidecut radius of 12 meters. The composites will be the same fiberglass I’ve been using consistently, the 20 oz Vectorply triaxial, and a 1″ wide strip of carbon fiber lengthwise down the middle of each ski.

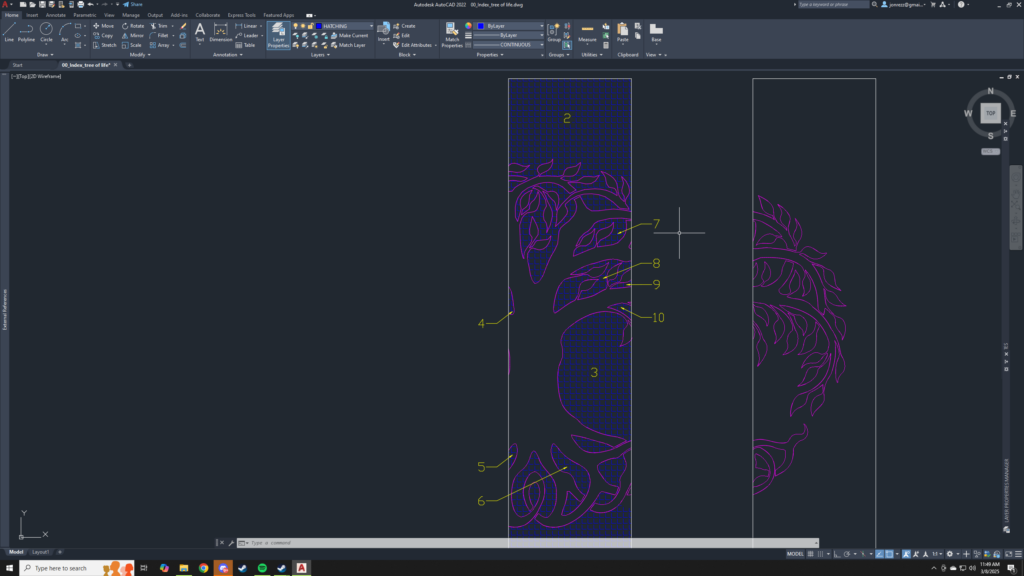

The top sheet is going to be a lot of work so I’m starting there on this one. It’s going to be a tree of life inlay out of rosewood and green dyed veneer on a lighter background like a cherry or similar veneer. First step is to get some options. I found that websites such as https://3axis.co/dxf-files/ are a great place to get some inspiration and vector files to start from. Once I had the tree of life that she likes, I scaled it and moved it around until I ended up with this:

On the left is a bunch of tree of life vectors I was able to get online, which came with about a dozen styles. In the center is where I scaled, adjusted and placed the magenta logo ontop of the skis (in red) and drew rectangles around the ski to define the bounds of my laser. Each topsheet will be a bit wider and longer than the topsheet to afford me some tolerance when laying it up. I added bindings to picture where those will sit relative to the graphics, and a logo at the tail. On the right is a final look at the design without any alignment lines, and with the graphics trimmed to the shape of the ski.

Next, the design needs to be configured for the laser engraver. I will clean up the linework that I have and convert splines to polylines, ensure the shapes are closed, and offset the shapes to account for the kerf of the laser itself. I read online that the offset should be approximately 0.02 mm but I’m going to do a test square and measure with calipers to see how much I really need to offset it.

Each piece (for example the blue hatching representing the background ones), will need to be cut from a sheet of veneer and then assembled by hand using veneer tape before it will be ready for the press. That’s it until next time!