Sidewall Beveling, Snowboard #2 & More

I’ll give the roller a shot on my next pair that gets plastic topsheet to see if I can get it flat.

some additional updates:

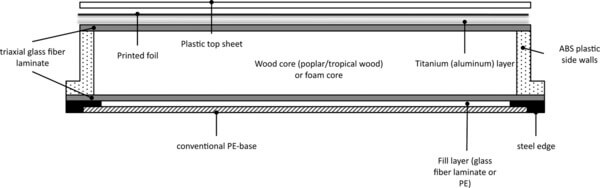

I have devised a new plan for sidewall beveling to allow me to get the “step” in the sidewalls like many brand name skis achieve:

hopefully will get something like this:

I’m going to stick it on a router table and create a wooden ridge for the ski to ride on similar to chrismp’s post a while back – very clever solution.

I’m also nearing completion on my 2nd snowboard, and it’s the best build yet! no flaws in sight! just need to drill out the binding inserts. I ordered some magnets with holes in them to locate and mark the insert centers.

next pair is going to be some skis again! (yay). the plan for this is to try some inlays and laser work instead of just plain veneer for the topsheet. they’re going to be 170 cm all mountain skis – about 95mm at the waist and 17m radius.

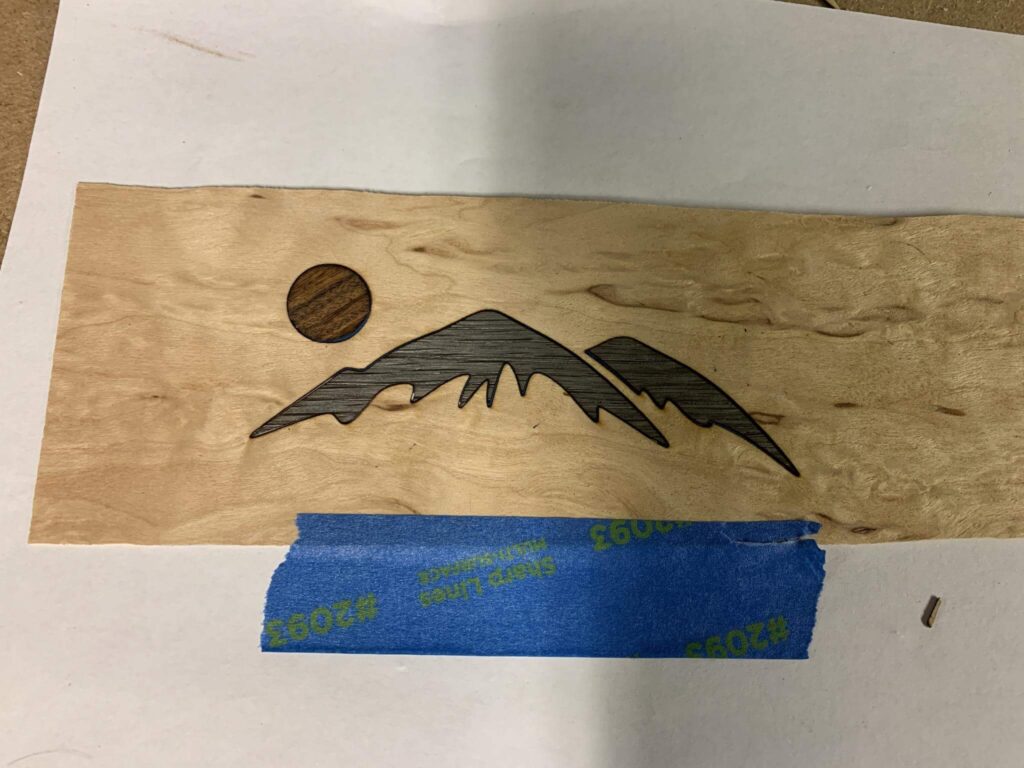

I got a laser engraver on aliexpress (neje master) and it’s been pretty simple to set up! I used the software it came with to control it, and made dxf files in autocad for the vector graphics:

worked pretty well in scrapwood for the tests! I’m hoping to do more large and complex inlays for the the ski, and experiment with stripes as well (gonna try veneer tape and a veneer saw with a straight edge) for the actual build.

in order to sort the base/core alignment issues I’ve been facing, here’s the plan:

they’re just dowel pins from the big box store and I drilled matching holes outside the ski for them to slip into. the pins are superglued into place on some scrap ptex in a similar manner that snowboard binding inserts are used for alignment.

lastly – my friend who I made the last board for and I took our equipment to gore last weekend! he liked the board!

hope you all are having a great winter! Cheers!