Adjustable Camber Mold Construction

This weekend I sketched up my concept for an adjustable camber mold! it’s designed to sit right on the table I’m using, and allows quick camber changes by inserting the correct sized “ribs” in the racks that go lengthwise. The basis of material is 3/4″ sheet wood or mdf. The tip and tail molds are held in place with threaded rod and there’s going to be holes spaced every 50mm down the length, and five holes spaced 10mm at the tail, allowing any length in 1cm steps . The tip and tail molds will still need to be created for each ski / board style, but I’m hoping this will cut down tremendously on the amount of mold making to create various camber/rocker / length boards and skis for my friends & I. here’s the sketches:

Assembly drawing with parts list. Part 22 and 23 are mcmaster carr part #s, one’s a washer and one’s a nylock nut:

The dimension for each rib is just how far it sticks out the top of the base – so add 12.7 to each for the full height of it..

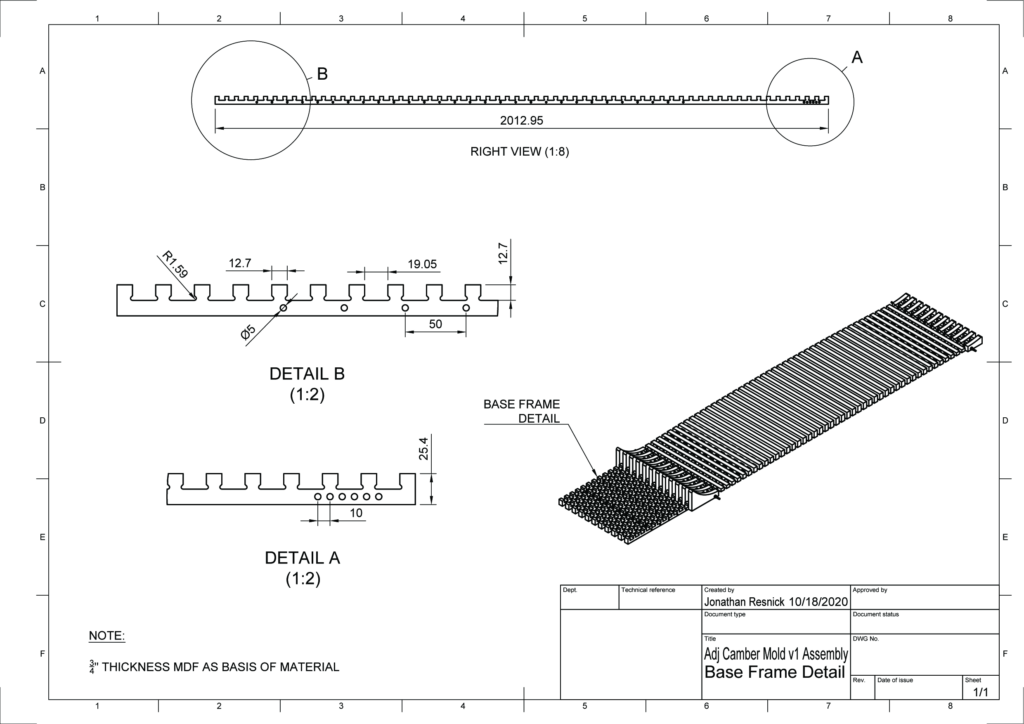

Base “rack” detail:

The radius in the bottom of each slot is just because the CNC won’t be able to cut a 90 degree inside angle so it allows room for the bit to create a flat surface for the rib to sit on.

Ultimately, I went with a modified version of it that collapses in on itself like so:

some progress I made today:

and here’s a timelapse of the CNC goin at it:

here she is! length is adjustable by removing the camber ribs and sliding the base of the mold in and out, and the camber is adjustable by replacing the camber ribs with different height pieces:

time to get the first non-test pair of skis prepped for layup!